Underdeck Insulation Materials

Underdeck Insulation Materials Specification

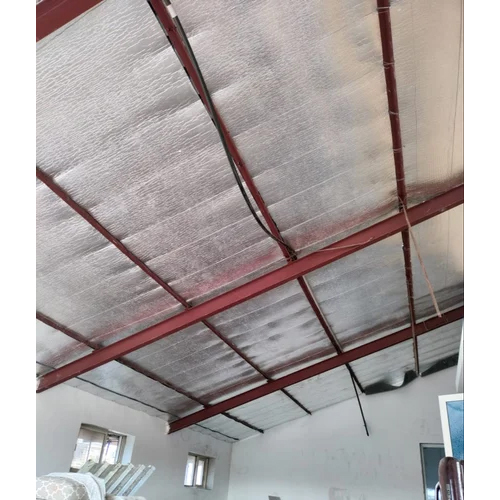

- Installation Guideline

- Placed beneath roof/ceiling, edges sealed and joints overlapped

- Density

- 40 Gram per cubic centimeter(g/cm3)

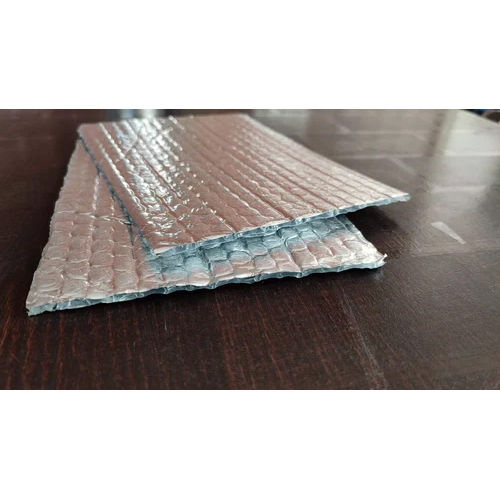

- Surface Treatment

- Aluminum Foil Laminated

- Coating Type

- Multi-layer Aluminum Foil

- Feature

- High thermal resistance, excellent durability, fire retardant

- Size

- Roll form, customizable

- Layer

- 3 layer (Insulation core with both side foil)

- Thermal Conductivity

- 0.023 W/mK

- Product Type

- Underdeck Insulation Materials

- Material

- Insulation

- Rated Voltage

- 230V

- Tensile Strength

- 15 kg/cm

- Width

- 1.2 Meter

- Thickness

- 50 mm

- Application

- Industrial

- Breakdown Voltage

- 16 kV

- Heat Conductivity

- 0.023 W/mK

- Color

- Gray

- Max Withstanding Temperature

- 120C

- Life Expectancy

- 25+ years under recommended usage

- Eco-Friendly

- CFC and HCFC free

- Odor

- Odorless

- Moisture Absorption

- < 1% by volume

- Acoustic Performance

- NRC up to 0.75

- Corrosion Resistance

- Yes (resists mildew, mould, corrosion)

- Compressibility

- Excellent

- Water Vapour Transmission

- < 0.1 perms

- Fire Class

- Class 0/Class 1 as per IS 12436

Underdeck Insulation Materials Trade Information

- Minimum Order Quantity

- 50 Square Meters

- Supply Ability

- 100000 Square Meters Per Week

- Delivery Time

- 1 Days

About Underdeck Insulation Materials

Competitive Advantages & Industrial Application Highlights

Underdeck Insulation Materials deliver remarkable fire safety, acoustic dampening, and prodigious thermal efficiency. They suit a range of industrial areas, providing sterling durability and moisture resistance even at extreme temperatures up to 120C. Applied beneath roofs or ceilings, surfaces must be clean and dry for optimal results. Edges are expertly sealed and joints overlapped, creating a unified thermal barrier that supports long-lasting comfort and energy savings across warehouses, factories, and commercial premises.

Sample Policy & Supply Ability in India

Underdeck Insulation Materials samples are offered with transparent handover policies, guaranteeing authentic shipped goods to every customer. Bulk deliveries are handed over promptly to domestic markets across India, reflecting a dependable supply ability from our network of dealers, distributors, and wholesalers. Customers can expect a seamless procurement experience, from order placement to installation support, ensuring materials arrive on time and in prime condition, no matter the destination or scale.

FAQs of Underdeck Insulation Materials:

Q: How should Underdeck Insulation Materials be installed for maximum effectiveness?

A: These materials are placed beneath the roof or ceiling, with all edges sealed and joints overlapped to form a continuous insulating barrier. Ensure the surface is clean for optimal adhesion and performance.Q: What competitive advantages do these insulation materials offer over conventional options?

A: They provide prodigious fire safety (Class 0/Class 1), moisture resistance, high thermal resistance, and eco-friendly construction, making them superior for industrial durability and long-term energy savings.Q: Where are Underdeck Insulation Materials commonly used?

A: These insulation materials are ideal for industrial settings including warehouses, manufacturing facilities, and large commercial buildings requiring enhanced thermal and acoustic control.Q: What is the life expectancy and maintenance requirement for these materials?

A: With a life expectancy exceeding 25 years under recommended use, these odorless, corrosion-resistant products require minimal maintenance, staying effective with proper initial installation.Q: Can Underdeck Insulation Materials be customized for different project needs?

A: Yes, they are available in roll form and can be customized in thickness, width, and length to fit specific project requirements, ensuring flexibility for various applications.Q: What benefits will dealers and suppliers experience in the Indian market?

A: Dealers and suppliers will gain from a hot-selling product backed by a reliable supply chain, competitive sample policies, and growing industrial demand, securing sterling business opportunities across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Insulation Material Category

Triple Layered Bubble Insulation Sheet

Price 118 INR / Square Meter

Minimum Order Quantity : 50 Square Meters

Product Type : Triple Layered Bubble Insulation Sheet

Application : Industrial

Material : Aluminum

Color : Gray

Bubble Wrap Insulation Material

Price 65 INR / Square Meter

Minimum Order Quantity : 50 Square Meters

Product Type : Bubble Wrap Insulation Material

Application : Industrial

Material : Aluminum

Color : Gray

Thermal And Acoustic Insulation Sheet

Price 150 INR / Square Meter

Minimum Order Quantity : 200 Square Meters

Product Type : Thermal And Acoustic Insulation Sheet

Application : Industrial

Material : XLPE

Color : Gray

Thermal Reflective Insulation Material

Price 78 INR / Square Meter

Minimum Order Quantity : 50 Square Meters

Product Type : Reflective Thermal Insulation

Application : Industrial

Material : Insulation

Color : Gray

Send Inquiry

Send Inquiry